Label Applicators

Label Applicators

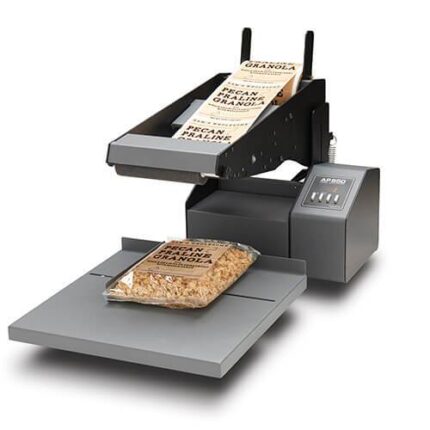

Label applicators effortlessly apply labels onto the product’s surface. As a result, label applicators streamline the labeling application and production process to be more efficient. It also ensures that the attached label on the product is well-placed. Thus, making it an essential part of the labeling process.

A label applicator’s primary operations are straightforward. The machine takes a roll of labels, peels the labels off the backing liner, dispenses, and applies them directly to the product’s surface. With a label application machine, you can label more products faster and more reliably, without wrinkles or creases, for a more professional end product. In addition, you can assure high-quality brand identification with a precise label on your products.

Manual vs. Semi-Automatic and Automatic Label Application

Hand-applying labels to a product is a time-consuming and imprecise operation. To guarantee that it is properly aligned, a great deal of attention to detail is required. Also, if a front and back label is necessary, such as wine or personal care products, this can be more complex. However, this is no longer an issue with label applicators available in manual, semi-automatic, and automatic versions.

A manual labeler operates without the use of power. It features an arm and a roller to maintain the container while the label is applied. Semi-automatic labeling is a mid-point for automation, speed, and size. An operator is needed to position the product and start the procedure on semi-automatic label applicators. The applications for automatic labeling are quick and fully automated. They are designed for more extensive operations and allow more customization. Manual and semi-automatic label applicators are available from ForeFront Label Solutions.

What Types of Label Applicators are Available?

For cylindrical containers, use bottle (round) label applicators. This applicator works with a wide range of tapered containers, such as bottles, cans, jars, tubes, and other circular objects. For single and double (front and back) label applications, various models are available. Many usages include wine bottles, beer bottles, shampoo containers, paint cans, cosmetic jars, and much more.

Flat label applicators make use of square objects and products with a flat surface. This sort of applicator works with rectangular containers, flat bottles, boxes, bags, pouches, lids, textiles, and other materials.

Finding the Right Label Applicator

What you look for in a label applicator will determine the right one for your business. There is a range of equipment available depending on the shape and size of your product. For example, the bottle label applicator is suited for cylindrical items, while the flat label applicator is suited for flat surfaces and objects. The majority of these label applicators do the task in a couple of seconds, allowing you to streamline the entire label printing and application operation.

We carry a wide range of label applicators in the United States. Also, a diversity of label handling equipment is available to make the application process easier and more efficient. Have questions about label applicators? Our knowledgeable customer service team can help.