Finishing Equipment

Label Finishing Equipment

Digital label finishing equipment is available to assist with the printing, label handling, and application process. Furthermore, the versatility of a finishing machine means it can adapt to your label printing, handling, and application tasks quickly. Designed for businesses of all sizes, they are ideal for small and large job operations.

What are the Functionality and Features of Label Finishing Equipment?

A finishing machine’s versatility means it can quickly adapt to your label printing, handling, and application tasks. Each category of devices is suited for small and large job operations. In addition, organizations of all sizes can use and employ them.

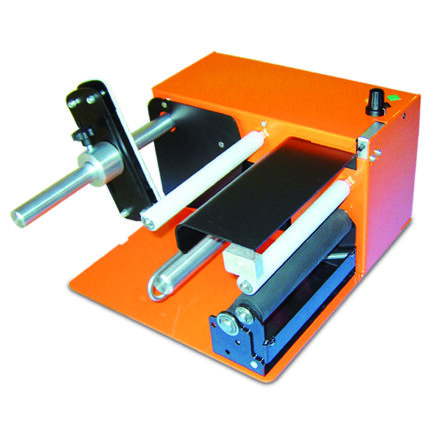

Applicators – Label applicators apply labels onto the product’s surface. The machine takes a label roll, dispenses the label, and adheres it to the product’s surface. It also ensures that the attached label placement is correct on the product. Capable of applying a single or double (front and back) label during application.

Label applicators come in two types: bottle (round) label applicators for cylindrical containers and flat label applicators for flat-surfaced products. Our label applicators are small, compact, and suitable for both manual and semi-automated operations. With both methods of operations, an operator is required for product positioning and to start the procedure.

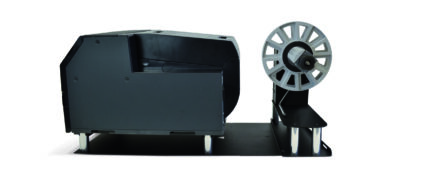

Counters – Label counters are a fast and convenient way to count how many labels are on a roll. Reel-to-reel label counters allow you to verify the exact quantity of labels on a roll accurately. The machine can stop at a pre-set number of labels and rewound labels onto a roll to a pre-set count. The ability to adjust the direction of labels as they come off the roll is also an option. In addition, a missing label detection feature is available on some models, which identifies a missing label with extreme precision.

Dispensers – Label dispensers advance the labels and stickers by providing them to you partially removed from the roll, allowing easy access to peel and apply them on demand. When you detach a label from the dispenser, it automatically replaces it with a new one ready to use. In addition, as the label peels off, the backing liner automatically rewinds to keep the process tidy. For your label rolls, label dispensers are the ideal peel-and-present option.

Matrix Removal – When labels are kiss cut with a die, the label material’s excess is label matrix. Matrix removal systems eliminate the waste that accumulates around die-cut labels. Thus, helping the printing process benefits from die-cut labels with matrix because they enable full-bleed (edge-to-edge) printing. In addition, slitters are usually built-in with the matrix removal equipment to complete the label finishing process. Consequently, operations can remove the waste matrix, slit multi-printed labels, and rewind rolls of labels onto cores from start to finish.

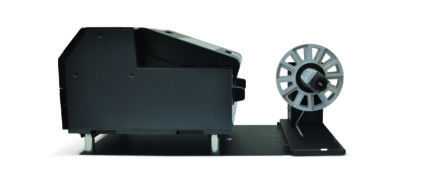

Rewinders – Label rewinders automatically collect printed labels and rewinds them into clean, uniform label rolls. This label machine can handle both small and large print tasks. It maintains the printed labels rewound and in place to be kept in inventory or ready for the label application operation of products.

Slitters – Label slitters can slit multiple-across label rolls into individual rolls. As a result, companies can increase the efficiency of their printing process by utilizing the entire print area (width of the label) from the same roll for color label printers. The label roll is slit and rewound onto singular rolls after the print run.

Unwinders – Label unwinders aid in making the printing process more efficient. Its primary function is to unwind a roll of labels continuously. As it feeds the labels into the color label printer, it keeps a steady pace. Fewer roll changes and a faster printing process result from the ability to manage larger rolls. Furthermore, larger rolls are often less expensive, providing for significant long-term cost savings.

Why Buy Label Finishing Equipment?

Feeding labels into the printer is the first step in the label printing process. Although most printers feature an internal label unwinder, an external unwinder has the advantage of retaining a bigger roll, which saves time by avoiding the need to stop the printing process and change rolls. As you print, manually rolling and applying labels when printing is cost-effective. As your company grows, though, this manual procedure will cost time and money.

As the volume of printing and label application grows, automating operations will reap significant benefits. Because label handling and finishing equipment can count, rewind, dispense, slit, and remove labels faster than humans can. Furthermore, they are capable of performing it with extreme precision and accuracy every time.

Automating the job at hand is the design of each finishing device. Therefore, it facilitates the efficient and precise completion of tasks. As a result, you’ll be able to save time, money and avoid human errors.

Which Label Finishing Equipment is Best Suited for My Business?

For your specific requirements, a variety of products are available. It’s crucial to know what kind of equipment to use and for what task. A rewinder and unwinder, for example, are beneficial to the printing process. The label application process benefits from dispensers, counters, slitters, and matrix removal.

Do you have any questions about the functionality of our finishing equipment? Our friendly customer service team can answer any questions you have and assist you in finding the correct labeling equipment in the United States for your needs. Reach us via email, chat, or phone.